Science Fair Mashup - Episode 08

Introduction

Engineers and scientists around the world dedicate their time and energy to solving real problems and learning more about our world. We wanted to find a way to highlight the achievements of these bold, visionary men and women by creating our own version of some of 2012's biggest moments. More than 10 engineers and artists worked together to make this science fair mashup masterpiece.

System Overview

The entire machine consisted of five modules each celebrating one engineering feat: Red Bull Stratos, SpaceX's Dragon Capsule, NASA's Mars Curiosity rover, the Tesla Model S electric car and CERN's discovery of the Higgs Boson. Each module was built to show a series of events that would trigger the next, in Rube Goldberg fashion.

Leap Motion and AR Drone

Our friends over at Leap Motion were kind enough to send us an early dev copy of the Leap Motion controller. If you haven’t already, check out this amazing new device. We wrote a custom LabVIEW interface for the Leap that allowed us to send commands to the AR Drone. The AR Drone is a consumer quadcopter that is controlled over WiFi and has a lot of built-in functionality. We used the AR drone toolkit from LabVIEWHacker.com to communicate with the drone. We got our hands on an alpha version of the LabVIEW Leap toolkit, which will release later this year on LabVIEWHacker.com after the Leap Motion device is released. Using the Leap, our application monitored the position of a palm above the sensor. When the palm goes above a certain threshold, the system sends a takeoff command to the drone. When the palm dropped back down, the AR drone landed.

Start Switch and Marble Ramp

The AR drone takes off from a large switch-landing pad made of foam core and popsicle sticks. It's rigged with rubber bands so it expands up once the drone takes off. The underside of the top is covered in aluminum foil, as is a small platform that keeps the switch from completely collapsing. When the drone takes off, a piece of foamcore is pulled out on a rubber band so when we send a signal for the AR drone to land, it closes the switch. Thus, our 9V battery powers a small DC motor, which turns a lever, which pulls a string, which releases out marble into the shoot. At the base of the ramp, a LEGO NXT color sensor that detects when the red ball is in place.

Software

Our custom LabVIEW interface allowed us to display the height of the palm on a slider and display the X,Y hand position over time on an XY graph. The screenshot here shows a hand moving in a figure 8 pattern. The Leap Motion can provide accurate hand targeting data, measuring more than 100 times a second. We were surprised at how accurate the measurements were into the millimeter range. The software for this module is available, but unless you have a dev unit from Leap and access to the developer SDK, you won’t be able to use it. You can still look at the code and use the AR drone parts.

Software Requirements

LabVIEW 2012

AR Drone Toolkit

Leap Motion LabVIEW Driver*

Leap Motion SDK**

*This download does not include the LabVIEW driver for Leap Motion SDK 6.0, Once Leap Motion releases sometime in early 2013 check LabVIEWHacker.com for a LabVIEW Driver.

**The Leap Motion SDK is not available for the public yet, developers only. :(

User Interface

Marble Ramp

The Landing Switch

Start Trigger

Arduino + NXT + Leap Motion + NI myDAQ + cRIO + iPad +AR Drone + LEGO MINDSTORMS EV3 = AWESOME

We created an awesome Rube Goldberg machine that celebrates the greatest accomplishments in science and engineering in 2012. See how we pay tribute to Felix Baumgartner, the SpaceX Dragon capsule, Mars Curiosity, the Tesla Model S, and CERN's discovery of the Higgs Boson at the LHC. We used lots of fun technology and plenty of hot glue, popsicle sticks, and duct tape. Turn on Captions for Technical Info

Redbull Stratos

On October 14, 2012, Felix Baumgartner made a historic journey, jumping out of a capsule 39 km over New Mexico and setting numerous records. Felix's feat required a huge team of engineers and scientists, who created the Red Bull Stratos capsule and his one-of-a-kind space suit.

Capsule

We constructed the capsule out of a few Red Bull cans and some pop rivets. Inside the capsule we placed a TETRIX 180º servo controlled with a PWM signal. This allowed the launch platform to tilt back and forth so we could eject "Wii-lix" at the right time.

Wii-lix

Using a Wiimote to represent Felix allowed us to monitor the acceleration and forces acting on it as it fell. However, in the final project we didn't use the live data since we didn't have a monitor to show it on. Since the capsule was already designed around the Wiimote, we decided to stick with it.

Paint Roller Banner Scroller

We used two paint rollers and a 40 ft strip of muslin to make a banner that could scroll down as Felix made his journey up. The banner was marked at regular intervals with the milestones ending at 39,045 m, Felix's peak altitude. The bottom paint roller was attached to a gear and a TETRIX DC Motor that would pull the banner down. The top roller was rigged with a system of rubber bands that provided friction to keep the banner from unrolling due to the weight of the hanging banner. We had to adjust the tension so only the motor would pull it down. To reset the banner, we used a cordless drill to speed things up.

Control System

We used a LEGO MINDSTORMS NXT with a TETRIX servo and DC motor controller. This allowed us to easily connect the motors to one base system, then use the NXT to control it all using LabVIEW for LEGO MINDSTORMS. This custom version of LabVIEW lets you prototype using a connected PC and joystick to manually drive the motors, then write the autonomous code and deploy it to the brick so it can run on its own.

SpaceX Dragon Capsule

On May 25, 2012, the SpaceX Dragon capsule became the first commercial spacecraft to ever dock with the International Space Station (ISS). For decades, NASA space shuttles carried the ISS into orbit, but with the retirement of the shuttle program, we have entered a new era of space travel. With several resupply missions scheduled in the near future, SpaceX will get lots of practice so they can refine their designs and code in time to be ready to transport humans by 2015. We wanted to pay tribute to the engineers and scientist at SpaceX and let them know we're cheering them on every step of the way!

Falcon Rocket

We used a SpaceX Falcon 9 and Dragon Model Rocket Kit as the rocket and capsule in our setup. The rocket attached to two guide rods made from copper wire and a DC motor at the top of the tracks launched the Falcon 9 via an attached string. At the beginning of the launch sequence, we had a red electroluminescent (EL) pad to represent the massive amounts of fuel that the Falcon 9 needs for successful delivery of the Dragon capsule. We used guide rods to make the rocket “wobble” as it ascended, as well as to make the launch more interesting. The launch is stopped by a Hall Effect sensor mounted near the top of the launch tracks, which detects the magnetic field of a magnet we mounted inside the tip of the rocket.

Dragon Capsule

The capsule was also made out of the same SpaceX Model Rocket Kit, and it is initially hidden behind a black box. Once the Falcon 9 rocket launch is complete, the capsule separates from the rocket at begins its journey to the ISS. It's propelled by another DC motor toward the ISS model. The ISS model is made from a folded paper kit and mounted in front of the pulley, which pulls the Dragon capsule close for docking.

EL Wire

Once the Dragon capsule docks with the ISS, a confirmation signal is sent back to earth, which is represented by four strands of EL wire. Each strand is controlled to light up one after the other with about one second of delay between. We did this to demonstrate electromagnetic propagation and that RF waves take time to travel.

Mission Control

Once the last strand of EL wire is lit, an LED lights up on the Mission Control Panel. This LED is monitored by a LEGO MINDSTORMS NXT program and light sensor. When the light level goes above a threshold the motor turns, causing our LEGO SpaceX engineers to rejoice! This pulls a string which releases the Hot Wheels car for the Mars Curiosity section.

Software Requirements

LabVIEW 2012

Control System

Behind the scenes, all the motors and lights were controlled by LabVIEW through an Arduino with the LabVIEW Interface for Arduino Toolkit. All the code was written in LabVIEW. The motors were connected to a DC Motor Shield and the EL wire was connected

Mars Curiosity Rover

In 2012, NASA's Jet Propulsion Laboratory (JPL) successfully landed the largest and most complex rover ever sent to Mars. The Curiosity Rover landed on Mars using an amazing array of engineering systems to slow it down as it entered the Martian atmosphere, finally touching down using a jet-engine-powered sky crane. The entry descent and landing was a AMAZING Rube Goldberg machine. The engineers and scientists who designed the rover now get to use the rover for years to come to learn more about Mars and determine whether it has the right environment to support life.

Hypersonic Aeromaneuvering

We made a small model of the entry module for the curiosity rover and placed it on a Hot Wheels car. We built a Hot Wheels track at the top of the board to represent the module entering the Mars atmosphere. At the end of the track is a LEGO NXT Push Button sensor. This alerts the LEGO MINDSTORMS NXT on the back of the board that the entry stage is complete.

Descent and Landing

The entire landing sequence is represented by foam cutouts in the shape of the heat shield, sky crane, and rover. After the NXT has received the notice that the push button on the track has been presse,d it begins the landing sequence. Two NXT motors on the back of the board wind and unwind a piece of string that is lined up across the Lander’s path on the front of the board. As the string is pulled toward the bottom, the foam cutouts move down the string’s path toward the landing site. When the lander reaches the back shell separation point, the foam cutout of the entry module is removed and a foam cutout of the sky crane appears. This happens again closer to the landing site when the sky crane is let go and the rover cutout is revealed beneath it. The rover continues down the path and stops on a LEGO NXT push button sensor at the base of the board, triggering the last stage.

EV3 Mars Rover

When the foam rover lands, the NXT will use its third motor to push open the left side of the board, revealing the LEGO model of the Curiosity rover, run by the new LEGO MINDSOTRMS EV3. The EV3 has a Ultrasonic Sensor that detects if the side of the board has been moved out of the way. The two motors on the rover power on and drive it up the hill. Once it has completed a set distance, the rover turns on its onboard laser. The laser is made of a simple laser pointer and two EV3 motors. The first motor turns a few degrees, completing a circuit and causing the laser to turn on. The second motor moves the laser left and right in a sweeping motion. When this happens, the laser will hit a NXT Light Sensor target. The light Sensor reports back to the NXT on the back of the board and causes it to play a series of musical notes to alert the next part of the machine.

Green Energy

One of the greatest engineering challenges of our time is building a sustainable energy system that can support the world’s growing demand. Advances in green energy production around the world are propelling the growth of renewable energy and providing a path to global sustainability. Our system shows solar, wind, and hydro power being used to charge a Tesla Model S performance electric vehicle. While engineers and scientists still have a lot of work to do, today’s innovations are an awesome foundation for the future.

Audio Recognition

Using a microphone connected to the NI myDAQ audio input, our application read in audio and detected the frequency content. Using an FFT and a lookup table, our code would return any loud notes detected and create a running history. When the NXT plays a sound, our NI myDAQ LabVIEW application would return a note string like “E5” or the 5th E on a piano. The program would then look for a particular pattern of notes so we could detect when the NXT played a song at the end of the Mars Curiosity section.

Solar

To represent the sun, we used a simple 100W incandescent bulb connected to a Power Switch Tail. This allowed us to turn it on and off using a TTL signal from the NI myDAQ device. We constructed a solar array using small solar cells wired in series. Together, they created about 9V when the light was on. We measured the voltage from the photovoltaics using the NI myDAQ device.

Wind

The wind power system used for blowers connected to a 12V line on a computer power supply. The computer power supply was connected to a Power Switch tail so we could control it with the NI myDAQ device. We had to short two pins together to get the power supply to turn on without a computer attached. The blowers created a sizable gust of wind for our Kid Wind wind turbine. This generator created a voltage we wired into the NI myDAQ device so we could monitor the power generated.

Water

We built a simple waterfall system to represent renewable hydro power. Using silicon epoxy and acrylic plastic, we made a tank with cascading ramps to control the water, and we used a pond pump to circulate the water. We also used a water wheel turbine to capture the energy of the falling water. Our design wasted most of the potential energy of the water with the cascading ramps, so there was barely enough water power to move the wheel. In hindsight our design should have imitated a real hydropower system and allowed the water to fall from its highest pointto capture the most energy.

Model S

We used an off-the-shelf slot car track and modded the slot car to look like a Tesla Model S. We created a green hill with some grass material and floral foam and wove the track around it by cutting a tunnel into it. We connected the track power to the computer power supply and then wired a analog output line from the NI myDAQ device to the controller input. Using a PWM signal, we could control how much power to give the car. We ended up using a signal with a duty cycle of 27% so the car wouldn’t crash through the barrier on a turn on run off the track.

Control System

NI myDAQ is a computer acquisition device designed for high school and university students. We used the Audio input to detect a song, then turned on the lights, blowers, and water pump using digital outputs connected to the Power Switch Tails. LabVIEW then displayed the voltages from the solar panels and wind turbine and used those values to charge a virtual battery. Once the battery was full, we turned on the car, which ran around the track and triggered the elevator to drop using a lever on the track.

Software Requirements

LabVIEW 2010 or later

myDAQmx

Download Coming Soon

CERN - Large Hadron Collider

In July 2012, the European Organization for Nuclear Research (CERN) announced that they had detected the Higgs Boson, which was first proposed in 1964. To do this, the engineers and scientists at CERN first had to build the world’s largest and most complex machine: the Large Hadron Collider near Geneva, Switzerland. This massive machine can accelerate protons to 99.9999991% the speed of light in opposite directions, then slam them together to create an explosion of subatomic particles whizzing through the air. Using ATLAS, the largest of the experiments along the LHC’s 27km ring, engineers and scientists can take a snapshot of all of these particles at the moment of collision. After performing detailed mathematical analysis of the collision, we can understand more about what we are made of, literally. The detection of the Higgs Boson proves that our understanding of physics is improving, and as it does we will be able to use the knowledge to conquer greater and greater challenges.

Particle Accelerator

To represent the particle accelerator, we used two loops of Tygon tubing with blowers in line so we could accelerate marbles in opposite directions. We wanted the marbles to spin up so you could see the particles accelerating, then hide just before the collision since they would be blown apart. We used two servos with a small coat hanger hooks that could block the path of the marbles and stop them in the back. With this system we could accelerate and stop the marbles in each tube.

ATLAS Collider

The real ATLAS collider is a complex system of thousands of sensors tuned to detect different subatomic particles. Our version is a lot less ambitious: we used a set of bike handlebar fiber optic lights to represent the paths of different particles. The lights came with multicolored LEDs that automatically cycled through different colors. We just needed to supply a voltage to turn them on.

Party Popper

We wanted to end our machine with a bang so we build a lever system out of popsicle sticks and used a continuous servo to pull the strings. The party popper took a surprising amount of force to pop so we used the lever arm and motor axis to gain some mechanical advantage.

Control System

The CERN module is controlled by an NI CompactRIO (Compact Reconfigurable Input/Output) device used for the FIRST Robotics Competition. The CompactRIO device uses a real-time processor and FPGA so it can be configured to control and monitor any kind of sensor or actuator very reliably. We created a few “Shared Variables” and connected the NI CompactRIO device to a wireless router so we could publish data to the WiFi network.

iPad Integration

Using the NI Data Dashboard App, we can connect to published Shared Variables and display the data in a custom interface. The app can arm, stop, and start the system. It also shows the current state of the machine. Once the CompactRIO device was programmed we used the iPad to control it.

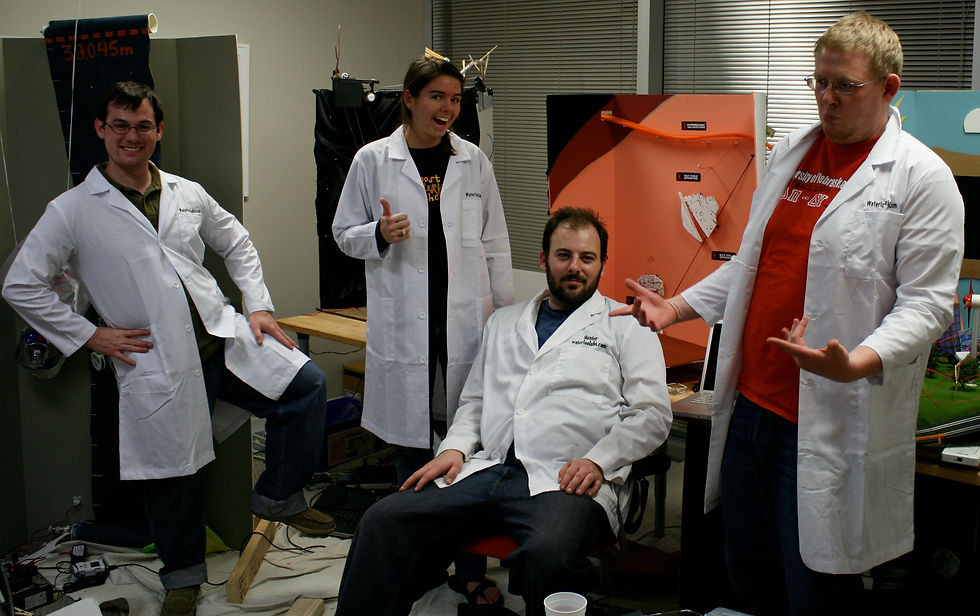

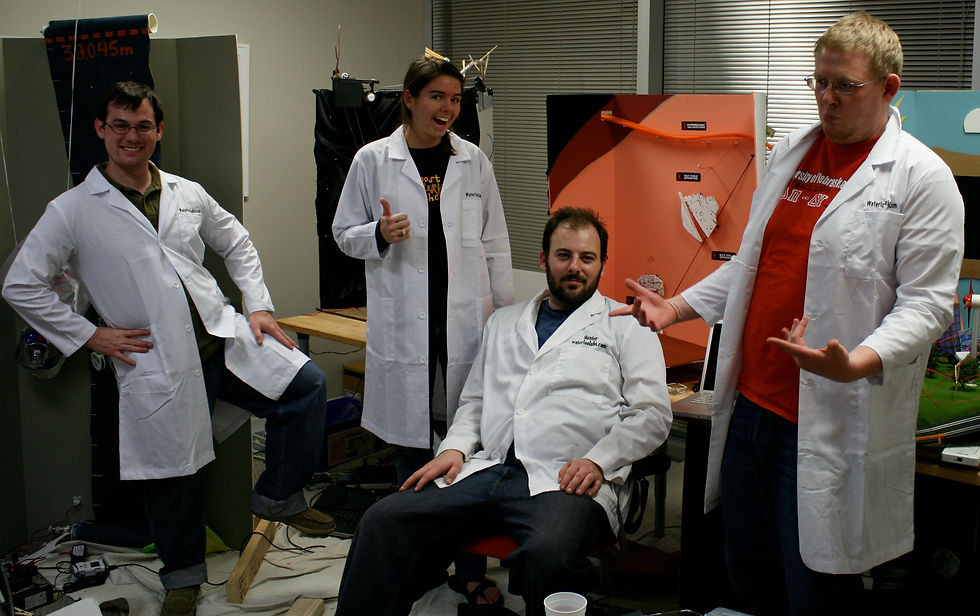

A huge thank you to this awesome group of engineers, scientists, artists, and tinkerers!

Ben James

Eric A. Levy

Jason Davis

Jeff Stasyszen

Kyle Hartley

Maggie Shaughnessy

Nathan Powelson

Ryan Sparks

Sunaina Kavi

Becca Salem

Dylan Caswell

Humphrey Huang

Laura Wright

Milan Raj

Nick Carlough

Patrick D. Williams

Stephen Kluchin

Tim Lynch

Chad Currie

Jeff Schanzer

to an EL Wire Driver Shield, both of which were connected and stacked onto the Arduino. This allowed us to control all the devices with digital signals through the Arduino. The Hall Effect Sensor was connected to one of the Analog Input pins on the Arduino, and the value was read as the rocket launched, and a loop waited for the signal to reach above a set threshold. The motor speed as well as the strobe effect on the EL Wire Launch Pad were both controlled by the PWM digital output pins on the Arduino, which allowed for a pseudo-variable voltage.